BOB BRIDGER, JONATHAN EARTHY, VIET DUNG VU

F.3.1 Introduction

BRIDGER

Many of the physical health hazards to which seafarers are exposed on board differ little from those to which workers are exposed ashore and include:

- Biomechanical hazards that put seafarers at risk of musculoskeletal injury:

- Injuries to the trunk when handling heavy equipment such as pumps and nets, sometimes exacerbated by the necessity to adopt stressful postures in confined spaces below deck.

- Injuries to the distal extremities caused by vibration, high forces or fast repetition of movement with additional risks due to backlash from winches or pulleys

- Injuries due to slips, trips and falls or being struck by moving objects

- Exposure to stressful environmental conditions when working on deck, for example, heat, cold, strong winds, noise.

These hazards are discussed in detail in recent publications and within the textbook in Chapter E2.

F.3.2 Specific hazards

Seafarers are also exposed to additional hazards that are particular to working at sea. These include

- vessel motion

- fatigue associated with long voyages

- sleep disruption/disturbance when working watches

- psychosocial stressors

- safety issues introduced or exacerbated by technological changes.

Vessel Motion

Pisula et al identified vessel motion thresholds for maintaining physical and mental performance in a study of naval personnel at sea[1]. The motions of interest were those arising from the interaction between the vessel and the external environment, including the sea state. Vibration from machinery and equipment was not part of the study. Personnel completed daily diaries while deployed in ships fitted with motion sensors. The physical effects of motion recorded were:

- Problems carrying and moving things

- Balance problems

- Sleep disturbed by motion

- Physically tired

- Mentally tired

- Abandoning tasks because of ship motion

In addition, the cognitive effects of motion were:

- Problems making decisions

- Issues with stomach awareness

- Taking too long to finish tasks

- Making mistakes

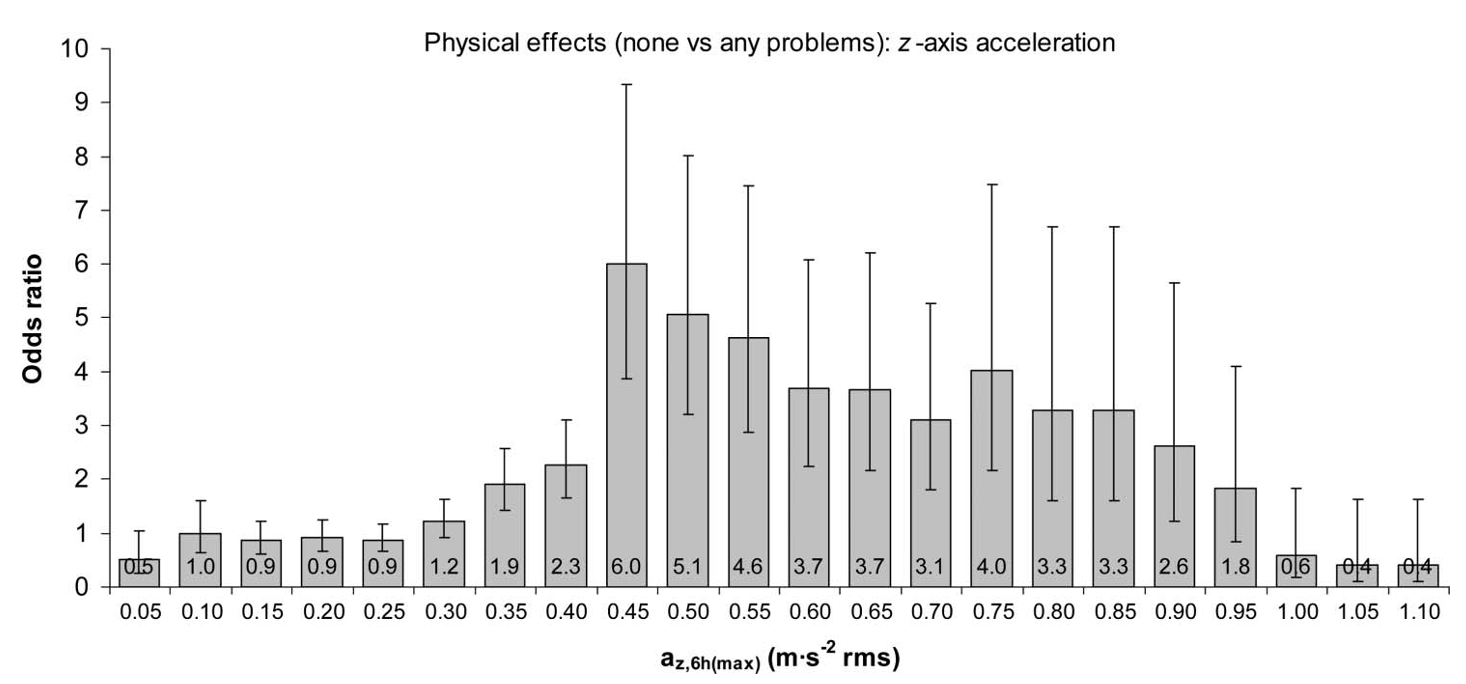

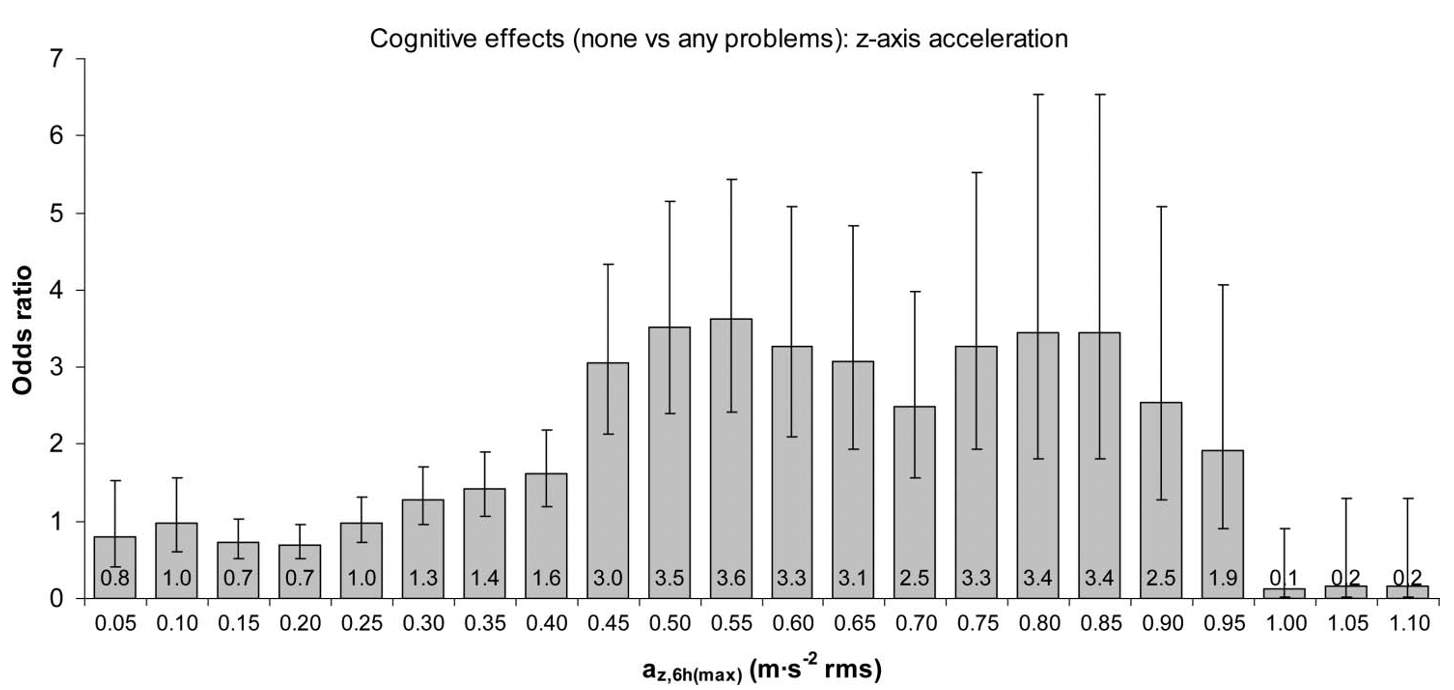

Figures 1 and 2 show the odds ratios (OR) for any physical or cognitive problems with different levels of deck motion. It is clear that a maximal OR of 6 occurs at 0.45 ms-2 rms. That is, physical problems were six times more likely to be reported when the 6-hour rms acceleration was 0.45 ms-2 or greater.

Ship motion amplifies the risks associated with all of the biomechanical hazards listed above and the cut-off value at which the risk increases rapidly is 0.45 ms-2 rms. This information is potentially useful for the designers of smaller vessels and, given suitable instrumentation aboard, might be of use to Masters for scheduling tasks. Over longer periods, motions of this magnitude may cause sleep disruption/deprivation.

Figure 2 shows the threshold for cognitive effects of vessel motion.

When the same analysis is performed for ‘cognitive effects’, an OR of 3.6 at is seen at an az,6h(max) of 0.55 ms-2 or greater. This indicates that the cognitive effects are less sensitive to motion than the physical effects.

Figure 1. Odds ratios for likelihood of any problems being reported with 95% confidence intervals for ‘physical effects’ as a function of the maximum 6-hour rms acceleration in the z-axis over the preceding 24 hours (pooled data from 779 daily diary responses). From: Pisula, P.J., Lewis, C.H. and Bridger, R.S. 2012. Vessel motion thresholds for physical and cognitive performance. A study of naval personnel at sea. Crown Copyright, contains public sector information licensed under the Open Government Licence v2.0.

Figure 2 Odds ratios for likelihood of any problems being reported with 95% confidence intervals for ‘cognitive effects’ as a function of the maximum 6-hour rms acceleration in the z-axis over the preceding 24 hours (pooled data from 779 daily diary responses). From: Pisula, P.J., Lewis, C.H. and Bridger, R.S. 2012. Vessel motion thresholds for physical and cognitive performance. A study of naval personnel at sea. Crown Copyright, contains public sector information licensed under the Open Government Licence v2.0.

Sleep Deprivation

Sleep deprivation has an indirect effect on the performance of many tasks and deficits are often not observed until an adverse event occurs. The main effect is to increase the effort required to maintain a given level of performance and to reduce the capacity to monitor one’s actions in relation to one’s intentions[2]. In 2009, Gould et al.investigated the effects of 60-hours of sleep deprivation on the high speed navigational performance of offshore patrol craft[3]. There was no effect on performance using either pencil and paper charts or an Electronic Chart Display Information System (ECDIS) although participants experienced more micro-sleeps using ECDIS suggesting lower arousal. Participants compensated for sleep deprivation by reducing speed. More information on sleep deprivation in the maritime environment is available in Ch xx.

Fatigue

Fatigue is not the same as feeling sleepy. The latter is caused by a lack of sleep, sleep disruption or being awake when one is normally asleep. According to Bridger (2018),fatigue is a consequence of work that lowers the capacity for work of the same kind. To impugn a state of fatigue is to imply the accumulation of some kind of deficit in the resources required to maintain performance. Work of the same kind is work that requires the same resources. Fatigue, therefore is specific to an activity whereas sleep deprivation leads to a general deficit that affects the performance of most tasks. In 2010, Bridger and Brasher investigated fatigue in seafarers on two occasions, either side of a period of 1-2 months at sea[4]. Even in those with physically demanding jobs, the main work factor associated with fatigue was frustration. There was no relationship between age and fatigue, which may be evidence of a survivor effect, but fatigue was greater at the second assessment.

F.3.3 Work Ability

Demographic changes in society are reflected on board ship. In some countries, seafarers are getting older and the prevalence of overweight or obese seafarers is increasing. A study of work ability of the crew of a vessel in the Mediterranean[5] demonstrated that work ability was found to decline with age, as expected, and was lower in obese seafarers than those of a healthy weight. A statistical model found work ability to decline at age 46 years in the obese compared to 56 years in those with a healthy BMI – an accelerated decline of 9 years in the obese.

F.3.4 Ergonomics design principles and processes (Earthy)

Ergonomics is the scientific discipline concerned with the understanding of interactions among humans and other elements of a system, and the profession that applies theory, principles, data and methods to design in order to optimise human well-being and overall system performance.

The following list presents the collated requirements of ISO 26800[6] and 9241-210[7]. Together these specify the fundamental principles of ergonomics and ergonomic design, required project activities and required organisational management activities.

- Identify and describe the environment in which a system, product, service or facility is intended to be used, taking full account of the nature of the task and its implications for the human.

- Design for the target population and the whole user experience.

- Drive and refine the design by user-centred evaluation and use of established ergonomic criteria.

- Include multi-disciplinary skills and perspectives in the design team.

- Consider human-system issues and the relative importance of ergonomics/human factors early and continuously in the project

- Identify user needs and specify the user requirements based on an explicit understanding of users, tasks, interactions and environments.

- Establish ergonomics criteria for the design.

- Include ergonomics and user requirements in design solutions.

- Take account of ergonomics criteria in conceptual and detailed design.

- Prevent negative effects by application of ergonomics principles.

- Identify appropriate methods and resources for human-centred design activities.

- Integrate these activities and their outputs with other system development activities.

- Feedback and communicate on human-centred design activities as they affect other design activities and trade-offs.

- Include and integrate human-centred design into the overall project plan and all phases of the product life cycle.

- Integrate milestones for human-centred activities into the overall design and development process.

- Allocate time for iteration and the incorporation of user feedback, and for evaluating whether the design solution satisfies the user requirements

- Identify the range of skills and viewpoints required.

- Involve workers or users (or potential workers or users) in the process

- Make individuals and organization(s) responsible for the human-centred design activities.

Additional information

Further, general information about ergonomics and the Human Machine Interface (HMI) can be found at:

- Alert! In general he-alert.org and Issue 40 in particular provides a map of all the things that might give rise to problems from an ergonomic perspective. https://www.he-alert.org/filemanager/root/site_assets/centrespreads/centreSpread_40.pdf

- IACS REC 132 for information on slips trips and falls and safe access/working environment iacs.org.uk/publications/recommendations/121-140

- Chapter 6 of the ILO guidelines for the implementation of the H&S requirements of MLC 2006 https://www.ilo.org/sector/Resources/codes-of-practice-and-guidelines/WCMS_325319/lang--en/index.htm

- Sea Health provides additional information and links to other sources. The ergonomics pages have a useful checklist and details at the right level for direct application shw.dk/ergonomi

F.3.5 Ergonomics risks associated with operations (Earthy and Vu)

ISO 6385:2016[8]Ergonomics principles in the design of work systems considers human beings as the main factor and an integral part of the system of work to be designed, including the work process, and the work environment. It sets principles and recommendations for the management of ergonomics risks. These principles should be used to ensure that ergonomics is considered in the design and operation of safety and other management systems in order to ensure understandable and workable procedures, checklists, permits, planning, reporting, means of managing problems and selection and use of tools and equipment.

Interactions

Consider major interactions between one or more people and the components of the work system, such as tasks, equipment, workspace and environment. These interactions create demands on the worker collectively described as the external workload. This results in reactions, called work strain, within the worker that will vary depending on individual characteristics such as size, age, capacities, abilities, skills, etc. Work strain has impairing effects, for example, fatigue generated by work, repetitive strain injury (RSI) and work related upper limb injuries (WRULDs), and facilitating effects such as skill development, that further affect the individual characteristics of the worker in a feedback loop. Ergonomic design optimises work strain by avoiding impairing and promoting facilitating effects. Unimpaired human performance improves system effectiveness and efficiency.

Ergonomics

Employ Ergonomics as a preventive function throughout the lifecycle rather than to solve problems after design is complete. The most important decisions that have consequences in the design are made at the beginning of the design process, for example, minimisation of high-risk activities such as working at height or in confined spaces, so particular attention should be paid to the application of ergonomics principles in the earliest stage of work system design. Although Ergonomics fits well into project risk assessment it can also be successfully employed in the redesign of an existing, unsatisfactory work system such as optimising heavy and awkward lifting or movement, adequate illumination, more usable equipment, re-design of information.

Involvement of workers

Involve workers in a participatory manner at all stages. The experience of workers provides an indispensable knowledge base. Work to construct, maintain, operate, and supervise each requires different considerations. In accordance with a human-centred approach, workers should be involved and should participate in the design and operation of work systems. This includes toolbox talks, allocation of sufficient people for a task and cross checking as work is carried out.

Target population.

The need for the development of special solutions for individual workers can be minimized, and the accessibility of the work system improved, by considering the needs of people with the widest expected range of abilities and in the range of foreseeable operating situations. and applying ergonomic principles to ensure that work systems are accessible to them. Such operating situations include normal, disturbed and degraded functioning. At the same time solutions should meet the range of size and strength required, particularly for PPE and access openings. Good luck and superhuman performance should never be expected, while fatigue, distraction and misunderstanding must be taken as everyday events.

Operating conditions.

The variety of operating conditions encountered includes but is not limited to:

- repetitive actions,

- time pressure,

- multiple, conflicting demands,

- enclosed space entry,

- effects of low manning,

- lone working,

- availability in emergencies,

- dealing with consequential injuries,

- use of PPE and dealing with PPE failures.

The exacerbation of effects by delay, lack of fitness and stress should also be considered.

On a day-to-day basis toolbox talks should address practical issues such as

- what's broken,

- people's experience and worries,

- are they fatigued, preoccupied or carrying injuries,

- the language(s) of the team,

- what needs checking,

- expected workload from tasks,

- other tasks that have to be done at the same time, and

- what to do if something goes wrong.

The National Institute for Operational Safety and Health (NIOSH) hierarchy of controls[9] criticises the use of administrative controls and PPE when hazards are not well controlled and proposes the removal of hazards as the best solution.

The UK P&I Club's Consolidated Risk Focus publication presents an analysis of major risks at sea and recommendations for mitigation[10]. Many of these hazards are related to procedural human factors.

Many aspects mentioned here are covered in greater depth in other chapters of the Textbook.

F.3.6 Ergonomics risks associated with the design of the ship (Vu)

The consideration of physical capabilities and limitations of the crew as part of the design of a ship is rarely addressed in the training and education of naval architects and marine engineers. The design and construction of ships and marine equipment still aims primarily to comply with existing regulations which, in turn, were established because of frequent and serious injury or long-term incapacity such as falls from height or hearing loss. This lack of a pre-active approach in design practice is evidenced in several ship designs that do not address key areas.

Areas to be considered

- easy movement around the ship,

- layout of work areas to suit the work,

- adequate ventilation,

- obtrusive noise,

- suitability of lighting,

- quality of accommodation,

- provision of recreation facilities,

- number and design of confined spaces,

- signs and markings,

- access and egress arrangements,

- size and strength of seafarers (anthropometrics),

- ease of cleaning and maintenance.

In addition there are specific concerns regarding the:

- location of sanitation,

- access to potable water in accommodation,

- quality of accommodation and recreational areas,

- transient noise,

- hazardous manual handing,

- fall protection arrangements,

- position of valves and maintenance access in engine rooms,

- size and location of manholes.

Consequences

The lack of consideration for ergonomics in ship design can cause negative consequences, inducing:

- slips, trips and falls,

- pinching/trapping (especially of hands),

- work-related back and upper limb disorders,

- fatigue/disturbed sleep,

- poisoning,

- asphyxiation,

- long-term medical effects,

- motion sickness,

- vibration,

- noise,

- head trauma,

- kidney stones,

- low fitness levels and

- reduced morale brought about by a perception of lack of concern for seafarers evidenced by the quality of both accommodation and the working environment.

Many of these topics are discussed elsewhere in the Textbook.

Future Trends in ergonomics

Increased automation on board will reduce or eliminate many of the traditional health hazards of working aboard ship. New hazards may emerge such as social isolation on board very lean-manned vessels and boredom amongst Masters of highly automated or remote operated vessels. Fully remote-operated ships will introduce new issues that may or may not represent health hazards. These include determining optimal work roles and work loading and finding flexible and appropriate ways of allocating functions to automation or operators. See section C.7.1 and Chapter F.4.9 for a summary of issues

[1] PJ Pisula. CH Lewis & RS Bridger. 2012. Vessel motion thresholds for maintaining physical and cognitive performance: a study of naval personnel at sea, Ergonomics, 55: 636-649.

[2] Bridger RS. 2018. Introduction to Human Factors and Ergonomics, 4th Edition. CRC Press, Boca Raton, Fl, pp 729

[3] Gould KS. Hirvonen K. Koefoed VF. Roed RK. Salinen M. Holm A. Bridger RS. Moen BE. 2009. Effects of 60-hours of total sleep deprivation on two methods of high speed ship navigation. Ergonomics, 52:1469-1486.

[4] Bridger RS Brasher K Dew S. 2010. Work Demands and Need for Recovery From Work in Ageing Seafarers. Ergonomics, 53:1006-1015.

[5] Bridger RS. Bennett AI. 2011. Body mass index interacts with age to determine work ability in seafarers. Occupational Medicine, 61(3): 157-162

[8] ISO 6385:2016 Ergonomics principles in the design of work systems. https://www.iso.org/obp/ui/#iso:std:iso:6385:ed-3:v1:en

[9] https://www.cdc.gov/niosh/topics/hierarchy/default.html

[10] https://www.ukpandi.com/knowledge-publications/publications/article/risk-focus-consolidated-2016-134790/